HOME > Production

Production Process

Fulfills the customer QDC with efficient processes of machining, painting, assembling and inspection.

Fulfills the customer QDC with efficient processes of machining, painting, assembling and inspection.

Johoku integrated manufacturing system

STEP1|Material procurement ( casting, forging, block, etc )

STEP2|Machining

STEP3|Surface treatment

STEP4|Assembling

STEP5|Inspection

STEP6|Shipping

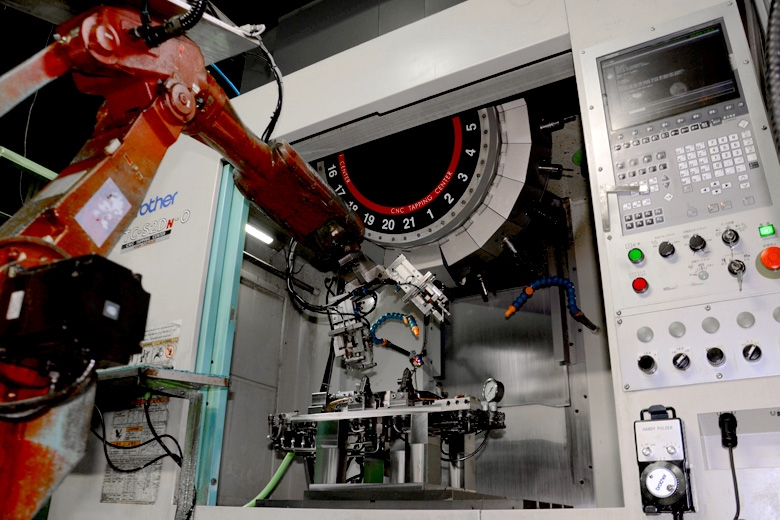

Machining process

●High accuracy & comple shape machining in a temperature-controlled room for an airplane and a racingcar etc.

●Minimum cost by selection of the appropriate size of machine in accordance with the product size.

●Flexible manufacturing system for high-mix low-volume production.

●Minimum cost by selection of the appropriate size of machine in accordance with the product size.

●Flexible manufacturing system for high-mix low-volume production.

[ Major facilities ]

- NC turning machine : 40unit

- Machining center :104unit

- TC:13unit

- General-purpose turning machine : 3unit

- Specialized machine :110unit

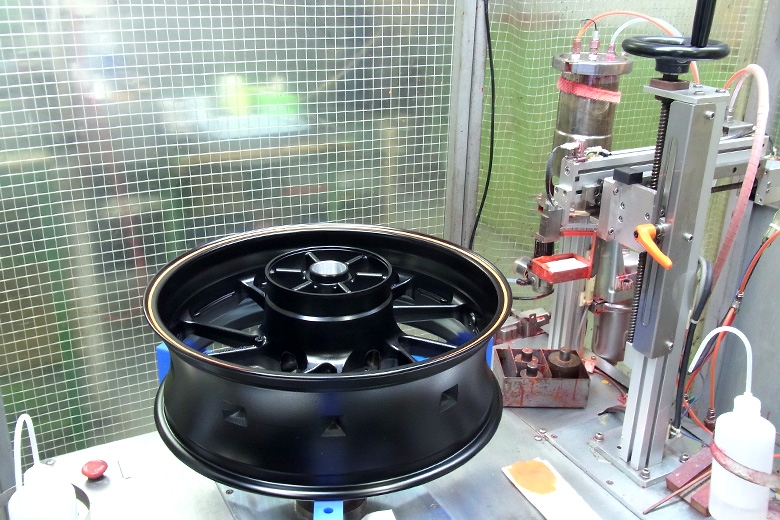

Painting process

To satisfying the customer need

・designs the masking shape

・variety of colors

・tacks products with complex shape

・visual inspection

Out live painting & coating 3D graphic out side of the live, enhance customer design.

・designs the masking shape

・variety of colors

・tacks products with complex shape

・visual inspection

Out live painting & coating 3D graphic out side of the live, enhance customer design.

[ Painting process ]

masking → preprocessing → painting → post processing → visual inspectionAssembling Process

Assembling process for a cast wheel and a spoke wheel is desinged considering high quality and automation.

Also complete management prevents the defective product.

Our well-kaizen assembling process fulfill customer QCD.

Also complete management prevents the defective product.

Our well-kaizen assembling process fulfill customer QCD.

[ Main assembling facilities ]

- Assembly line for front wheel

- Assembly line for rear wheel

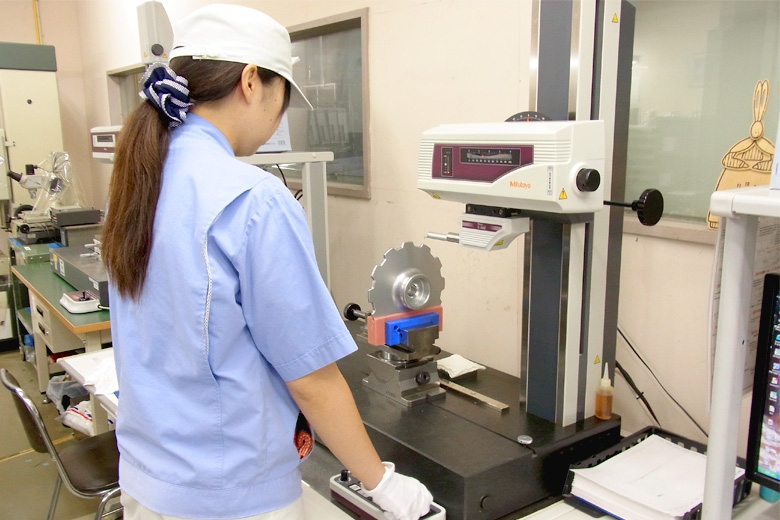

Quality Control

Quality is our competing power. We enhance the product quality with software and hardware side countermeasure.

And provide high quality products from single items to assembling products.

And provide high quality products from single items to assembling products.

[ Main measuring instrument ]

- High speed & high accuracy CNC 3D measuring instrument :3unit

- High accuracy surface roughness measuring instrument :2unit

- High accuracy contour shape measuring instrument :1unit